|

|

Technical data |

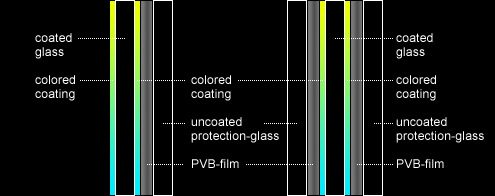

Dichroic glass of Variotrans© is usually used for art objects and architecture as double or triple-laminated glass (laminated safety glass with PVB foil). For better cleaning and for protection from exterior damage of the coating, we recommend strong cover panels for external use - a triple-laminated glass with at least 3 mm thickness. Naturally, the calculation of the glass thickness depends on the specific requirements of the project.

For use within interior spaces or for glass art, the coated glass can be used, depending upon the application, as either laminated glass or as single glass. Double-laminated safety glass Triple-laminated safety glass By using only low-iron glass, we guarantee the genuine colors in their extraordinary processes with the highest natural brilliance.

We can build the glass components to your specifications, using your tolerances. We can also make them with frames or without frames depending on your needs. Coating

The dichroic glass is manufactured using a dip coating process. The metallic-alcoholic coating solutions used are converted in a thermal process at 480°C into an adherent metallic oxide layer. This process gives a good stability, which means good longevity and problem-free handling and workability.

The coated glass is characterised by high stability and usefulness. It can be processed with almost all standard methods used in glass processing.  Sizes

- maximum size 5800 mm x 2550 mm connected with laminated joint (e. g. as mosaic)

- standard size 1080 mm x 800 mm, other sizes available on request

Mosaic glass (using several pieces of glass to make one panel) can combine different colors and color gradients in one plate. Semi-permeable mirrors and clear glass may also be used in the panel. |

| Copyright 2006 Prinz Optics | Imprint | Privacy |